FAQs

FAQs

Q. How do I begin to shop for cabinets?

A. Our website is a good start! Learning about cabinets, countertops and accessories will make your decisions easier. It’s important to be actively involved in the details of planning of your kitchen. Leaving all the decisions up to your kitchen designer may not end in the results you want. So be sure to convey your ideas for your new kitchen…how it blends into the rest of the home, whether it will be used for entertaining…and any special requirements you may have.

Q How can I set a realistic budget for my kitchen?

A. Separate big ticket items: Cabinets, Countertops, Appliances, Flooring, etc. Then research your options and go shopping! Get at least two quotes on each item. Then add up the costs…you’ll have a high and low number. Your budget is somewhere between the two.

Q How can I get a new kitchen on a small budget?

A. Cabinets make up a large portion of the overall cost of a kitchen, and their costs vary greatly. Things that impact the cost of cabinetry include:

- Materials used to produce the cabinet box, door and drawer.

- The wood species.

- The door style.

- The type of overlay for the door and drawer fronts.

- The application of any stain, glaze or other finish

- The quality of hardware components (hinges, slides and pulls).

- The variety of available cabinet sizes.

- The variety of available accessories in a particular line of cabinets.

When talking with your designer it is best to be candid about your budget as well as your design priorities. A good designer will show you cabinetry that will allow you to stay within your budget and provide the most important features you want. Look for quality, value for the price and service. Always try to compare “apples to apples” on the different features and finishes. Remember that your cabinets are a more permanent part of your home, as opposed to appliances and countertops.

You’ll find countertop prices vary as much as cabinets due to the wide differences in materials. Plastic laminate countertops are the least costly and come in hundreds of designs. You can also save by installing cabinets yourself. We can offer you tips on tackling the job on your own. And a good designer can make the installation process easier for DIY-ers if you know you’ll be doing it yourself.

Q. How do I choose a designer?

A. The single most important step in achieving your goal of a dream kitchen is the choice of a designer. You need someone who is knowledgeable about the products, has experience designing kitchens, and who listens to your requirements and will incorporate them into the design. Your designer should educate you on the basics of cabinet design and styles as well as the pros and cons of your final design. If you feel comfortable with your designer, the purchase process will be enjoyable!

Q. What type of wood is right for my kitchen? A. There are literally hundreds of wood species, paints, stains and glazes to choose from, making the selection process very challenging. Do you like dark or light wood? Do you prefer a subtle or more pronounced grain structure? What types of wipes or glazes would you favor choosing, or definitely rule out?

If you know what your walls and floors will be, consider using a wood color that will contrast with them. Too much of a good thing can become boring if the colors tend to blend. Or it can be overwhelming if there is too much grain structure, such as knotty pine or hickory cabinets in a log home kitchen with solid pine walls. Using a subtle grained wood in a contrasting color, such as natural knotty cherry, gives the cabinetry separation from the walls and lends definition to the overall look of the kitchen.

Q If I’m remodeling, does it make sense to re-do the kitchen I have while keeping the same cabinet boxes? A. In some cases, yes. If the cabinet boxes are in good condition and the layout of the kitchen works well, then a kitchen re-facing may be right. We will assess your kitchen to help you determine if re-facing is a good option.

Q. What are the pros and cons of face frame cabinets vs. frameless cabinets? A. Face frame cabinets, standing independently, are sturdier and stronger than frameless cabinets because they have a frame bracing the front of the cabinet opening. However, when frameless cabinets are screwed together in multiples and then screwed to the wall, they are as sturdy as they need to be.

Frameless cabinets are also called “full access cabinets” because the interior of the cabinet is wide open compared to a framed cabinet, which typically has an opening that is about 2” narrower than the cabinet interior. Doors on framed cabinets open wider than doors typically found on frameless cabinets.

Doors for face frame cabinet are available in a variety of styles, including standard overlay, full overlay, half inset and full inset. Doors for frameless cabinets are available only in full overlay. The various overlays create different appearances for your kitchen.

Understanding the difference between framed and frameless cabinets is a good first step toward narrowing down the type of cabinetry style that is right for you.

Q How do I choose the material for my counter tops?

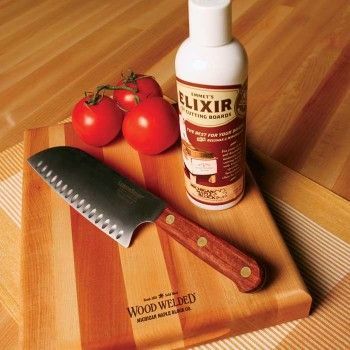

A. First set your budget for counter tops. Plastic laminate is least costly. Solid surface material such as Corian is next, and stone surfaces such as granite and quartz are most costly. Other options for counter tops include solid wood butcher block, cement or glass surfaces. Using different materials on the perimeter and island can be a good way to meet budget constraints.